What components constitute a fully continuous pyrolysis machine?

In the realm of waste recycling and resource recovery, pyrolysis technology stands out as a highly efficient and environmentally friendly approach. As a leading manufacturer of pyrolysis machines, DOING Company is dedicated to providing advanced fully continuous pyrolysis machines to help customers achieve maximum economic and environmental benefits.

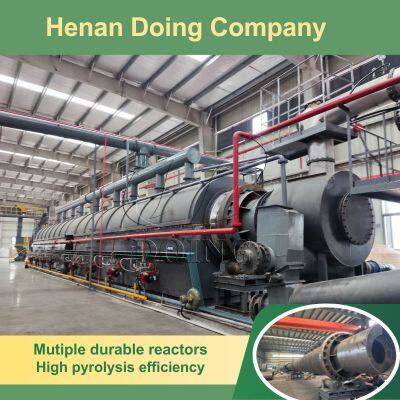

DOING fully continuous pyrolysis machine

Below is a detailed introduction to the key components of our fully continuous pyrolysis machine:

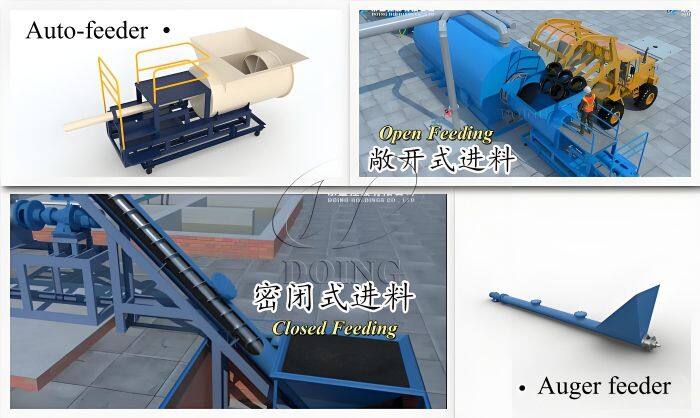

Continuous Feeding Machine

The continuous feeding machine serves as the gateway to the entire pyrolysis process. It ensures a steady supply of raw materials into the reactor, avoiding interruptions caused by intermittent feeding and enhancing production efficiency.

DOING pyrolysis machine feeding methods

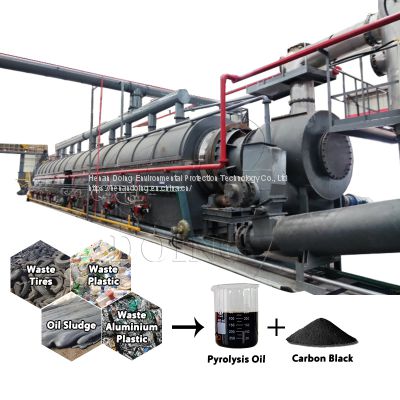

Pyrolysis Reactor

The pyrolysis reactor is the core component of the fully continuous pyrolysis machine, where the pyrolysis reaction takes place. DOING Company utilizes high-quality materials and advanced manufacturing processes to construct reactors with excellent heat resistance, corrosion resistance, and pressure resistance. Our reactors feature efficient heating machines that can rapidly and evenly raise the temperature to the pyrolysis reaction range. This ensures thorough pyrolysis of the raw materials, maximizing the yield and quality of pyrolysis products.

DOING fully continuous pyrolysis machine reactor details

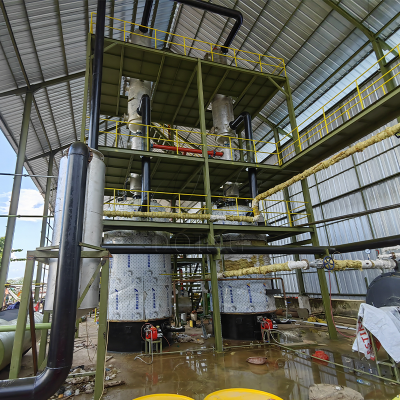

Condensation Machine

The condensation machine is responsible for cooling and liquefying the pyrolysis gases produced in the reactor, converting them into liquid products such as pyrolysis oil. DOING Company's condensation machine adopts multi-stage condensation technology, using water-cooled condensers. This effectively reduces the temperature of the pyrolysis gases and increases the condensation efficiency of the oil vapors. The machine can recover a significant portion of the pyrolysis oil, improving resource utilization. Meanwhile, the uncondensed gases are directed to the gas purification and recycling machine for further processing.

DOING fully continuous pyrolysis machine condensation machine

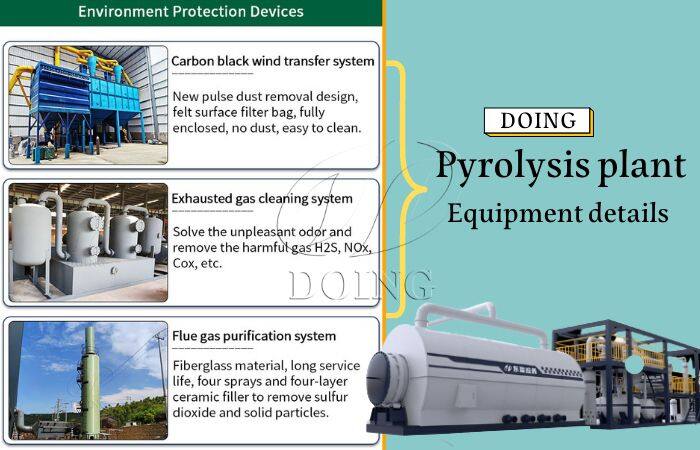

Gas Purification and Recycling Machine

The gas purification and recycling machine plays a crucial role in ensuring the environmental performance and economic benefits of the fully continuous pyrolysis machine. It purifies the non-condensable gases from the pyrolysis process, removing harmful substances such as dust, sulfur compounds, and nitrogen oxides. DOING Company's gas purification and recycling machine employs multiple purification technologies, including dust removal, desulfurization, and de-nitration, to treat the gases and meet stringent environmental emission standards. The purified gases can be recycled as fuel to support the heating of the pyrolysis reactor, reducing energy consumption and lowering operating costs.

DOING pyrolysis machine environment protection devices

Continuous Discharge Machine

The continuous discharge machine ensures that solid residues (such as carbon black and slag) generated during the pyrolysis process are discharged in a timely and stable manner. It prevents blockages and ensures the continuous operation of the machine. DOING Company's continuous discharge machine features a unique discharge mechanism and sealing design that can smoothly discharge solid residues while maintaining the anaerobic environment inside the reactor. The discharged residues can be further processed and utilized, such as carbon black being refined for use in rubber products or as fuel, achieving full resource utilization.

DOING fully continuous pyrolysis machine carbon black lifting auger

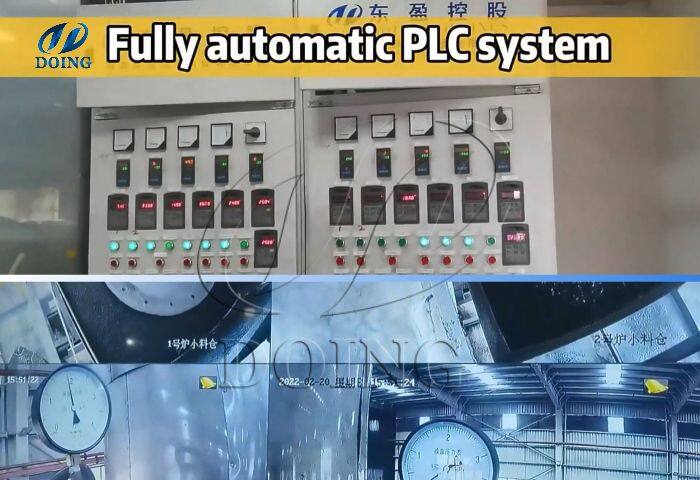

Automatic Control Machine

The automatic control machine serves as the "brain" of the fully continuous pyrolysis machine, overseeing and regulating the operation of all components. DOING Company's automatic control machine employs advanced sensors, programmable logic controllers (PLCs), and monitoring software to achieve precise control and real-time monitoring of parameters such as temperature, pressure, and flow rate throughout the pyrolysis process. Operators can conveniently operate and manage the machine via a human-machine interface (HMI), enabling automated production and reducing labor intensity and operational errors. The automatic control machine also features fault diagnosis and alarm functions, promptly identifying and addressing abnormal conditions to ensure stable and safe machine operation.

DOING pyrolysis machine fully automatic PLC machine

DOING Company's fully continuous pyrolysis machine, with its comprehensive and advanced components, offers customers a reliable and efficient pyrolysis solution. Whether you need to process waste tires, plastic waste, or other materials, our machine can deliver high pyrolysis efficiency, high-quality products, and significant economic returns. Choosing DOING Company's pyrolysis machine means opting for excellence and innovation. We are committed to providing you with top-tier equipment, professional technical support, and comprehensive after-sales service, accompanying you on your journey toward sustainable development.

Recently Posted

-

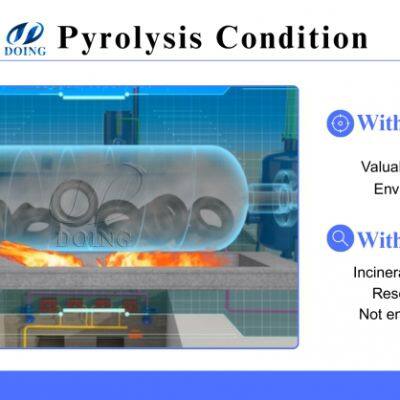

Why is Oxygen Not Needed in Pyrolysis?

February 24, 2026Pyrolysis involves thermal breakdown of substances in an environment lacking oxygen or other reactive gases. The key factor for av Read More

Read More -

Key Considerations in Pyrolysis Machine Costs and Purchase Decisions

February 5, 2026The cost of pyrolysis machines is influenced by a range of factors, including machine type, processing capacity, material qua Read More

Read More -

The Superior Advantages of Plastic Thermal Cracking Compared to Conventional Recycling Methods

January 30, 2026Plastic pollution represents one of today’s most urgent environmental issues. Although conventional plastic recycling plays a role Read More

Read More -

Is Pyrolysis Oil Usable as Fuel for Cars or Vehicles?

January 21, 2026Pyrolysis oil, produced through thermal decomposition of waste materials like tires and plastics, isn’t suitable for direct use in Read More

Read More