Can one make money from scrap tyres?

Traditionally, waste has often been regarded as worthless, suitable only for disposal. However, certain waste materials, such as end-of-life tyres, retain significant reusable value. Against this backdrop, let us delve into the commercial opportunities within the end-of-life tyre recycling sector.

Current State of End-of-Life Tyre Recycling

China currently leads the world in end-of-life tyre production, generating approximately 260 million units annually – equivalent to nearly 9.5 million tonnes. The annual growth rate of scrap tyres remains between 8% and 10%, yet the recycling rate hovers around 50%. This not only represents a significant waste of resources but also poses severe environmental hazards. Indiscriminate dumping of scrap tyres occupies valuable space, breeds mosquitoes, and spreads disease. Open-air burning releases substantial quantities of harmful gases, posing serious threats to air, soil, and water quality. Therefore, recycling waste tyres holds significant importance for both resource conservation and environmental protection.

Globally, the pollution issue from waste tyres is equally severe. Countries including Kuwait, Indonesia, Laos, Nigeria, India, Vietnam, South Africa, Canada, and Australia all face this challenge and are actively seeking effective solutions. Against this backdrop, enterprises specialising in tyre recycling—particularly in the pyrolysis recycling sector—present vast development opportunities.

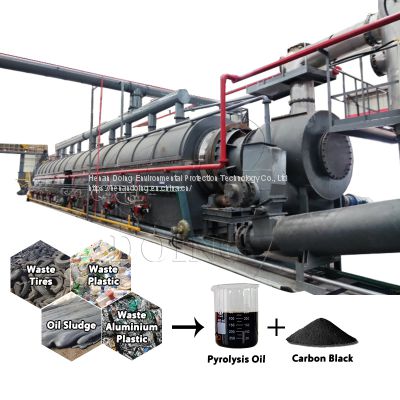

Waste tire pyrolysis raw materials

Profit Models for Waste Tyre Recycling

Retreading Waste Tyres: Retreading involves repairing worn tyres to extend their service life. However, this method yields low profit margins and is constrained by market demand. The process is complex and requires stringent quality control. Tyres failing to meet retreading standards may pose safety hazards, limiting the large-scale development of the retreading industry.

Production of Tyre Rubber Powder: Rubber powder derived from waste tyres finds applications in rubber goods, plastic products, coatings, and building materials. Yet recent years have seen market saturation for rubber powder, coupled with high production equipment costs driving down profit margins and diminishing investment appeal.

Pyrolysis of tyres for fuel oil: Tyre pyrolysis technology decomposes waste tyres through oxygen-deprived heating, yielding fuel oil, carbon black, steel wire, and combustible gases. Among various processing methods, pyrolysis recycling technology has garnered significant attention due to its distinct advantages.

Common methods of recycling waste tires

Advantages of Tyre Pyrolysis Recycling

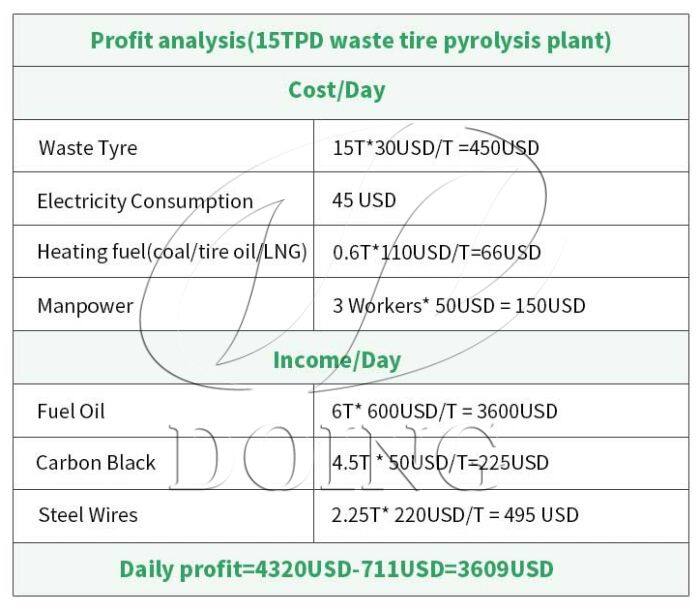

High resource utilisation and significant economic benefits: Pyrolysis technology converts waste tyres into multiple high-value products. Approximately 45% of the output comprises fuel oil, suitable as heating fuel for cement plants, power stations, paper mills, and steelworks. Its calorific value rivals that of light diesel, making it an economical alternative to traditional fossil fuels. Carbon black accounts for 30% of the output, which can be further processed into high-value-added products such as rubber goods and printing inks. The 15% steel wire content can be recovered for use in smelting plants. The remaining 10% comprises combustible gases, which can be recycled to power the pyrolysis process, thereby reducing energy costs. This process achieves nearly 100% resource recovery from waste tyres, maximising economic benefits. Based on a profitability analysis for a 10 tonnes per day tyre pyrolysis recycling facility, investors can earn approximately US$1,700 per tonne of waste tyres processed.

DOING waste tire pyrolysis machine profit analysis

Moreover, in numerous European, Latin American and Asian nations, cement works, power stations, paper mills and steelworks utilise fuel oil derived from the pyrolysis of waste tyres as heating fuel. This practice yields significant benefits, not only reducing production costs but also addressing the environmental challenges posed by waste tyres.

Environmental Benefits and Policy Support: Pyrolysis recycling technology effectively resolves environmental issues stemming from waste tyres, reducing pollution while promoting sustainable development. Governments in some European countries not only subsidise the acquisition of pyrolysis equipment but also prioritise the use of recycled products in public projects. These policies not only mitigate corporate investment risks but also significantly enhance profitability.

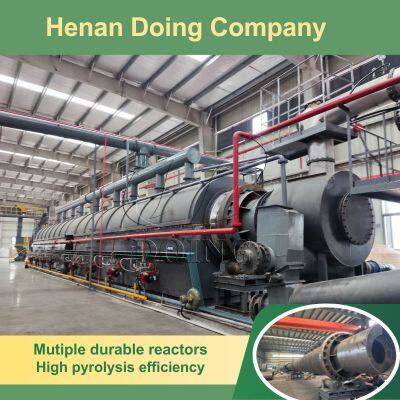

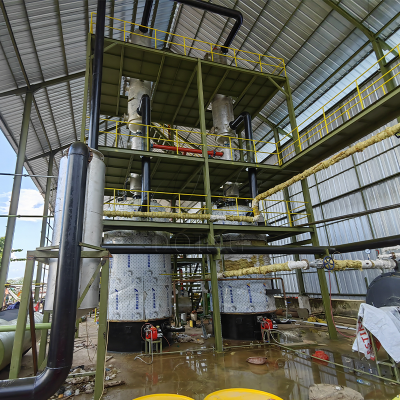

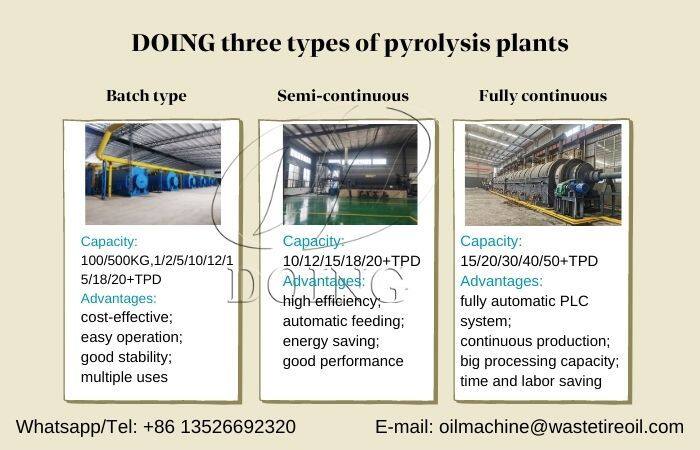

DOING waste tire pyrolysis machine manufacturer

In summary, the recycling of end-of-life tyres—particularly through pyrolysis technology—holds significant profit potential. This approach not only addresses environmental pollution concerns but also generates substantial economic returns. Enterprises such as Duoxing are dedicated to providing advanced tyre pyrolysis recycling equipment and technical support, empowering more clients to achieve success within the tyre recycling industry. Should you have any requirements related to tyre pyrolysis recycling, please do not hesitate to contact us.

Recently Posted

-

Why is Oxygen Not Needed in Pyrolysis?

February 24, 2026Pyrolysis involves thermal breakdown of substances in an environment lacking oxygen or other reactive gases. The key factor for av Read More

Read More -

Key Considerations in Pyrolysis Machine Costs and Purchase Decisions

February 5, 2026The cost of pyrolysis machines is influenced by a range of factors, including machine type, processing capacity, material qua Read More

Read More -

The Superior Advantages of Plastic Thermal Cracking Compared to Conventional Recycling Methods

January 30, 2026Plastic pollution represents one of today’s most urgent environmental issues. Although conventional plastic recycling plays a role Read More

Read More -

Is Pyrolysis Oil Usable as Fuel for Cars or Vehicles?

January 21, 2026Pyrolysis oil, produced through thermal decomposition of waste materials like tires and plastics, isn’t suitable for direct use in Read More

Read More