What types of oils can pyrolysis processes produce?

As a leading manufacturer in pyrolysis equipment, DOING is committed to delivering innovative and efficient solutions for waste-to-energy conversion. Our pyrolysis technology not only supports waste management but also produces valuable oils applicable across multiple industries.

Waste to oil pyrolysis process

Understanding Pyrolysis

Pyrolysis is a thermal decomposition process occurring under oxygen-deprived conditions. This process breaks down complex molecular structures into simpler compounds by heating organic materials to high temperatures, typically between 300°C and 600°C. The resulting mixture comprises solid, liquid, and gaseous components, with the liquid fraction being pyrolysis oil.

Types of Oils Obtained from Pyrolysis

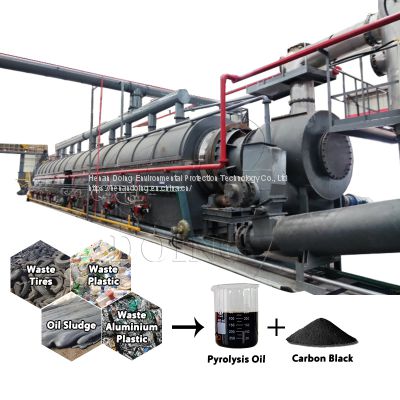

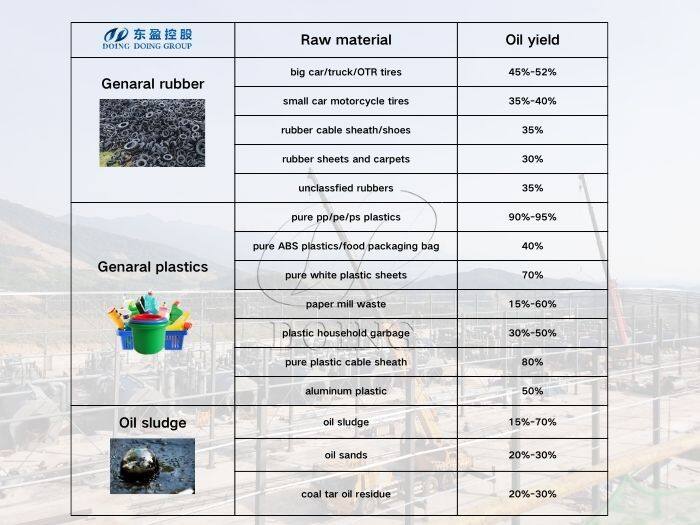

The type of oil obtained from pyrolysis primarily depends on the feedstock used. Below are common pyrolysis oil types:

Plastic Pyrolysis Oil

When waste plastics such as polyethylene (PE), polypropylene (PP), and polystyrene (PS) undergo pyrolysis, they decompose into light hydrocarbons. The resulting oil is a mixture of light and heavy fractions, which can be further refined into diesel and other fuel products. This oil is highly valued for its high calorific value and low sulfur content, making it suitable for industrial heating applications and as a substitute for traditional fossil fuels.

Tire Pyrolysis Oil

Composed of natural and synthetic rubber, waste tires undergo pyrolysis to produce tire pyrolysis oil. Upgraded, this oil can be converted into fuels such as diesel and heavy oil, widely used in power generation units and industrial applications. Renowned for its stability and compatibility, tire pyrolysis oil offers a cleaner alternative to traditional fuels.

Oil Sludge Pyrolysis Oil

As a byproduct of petroleum extraction and processing, oil sludge is rich in petroleum hydrocarbons. Pyrolysis treatment yields oil products suitable for diverse industrial applications. This process also effectively mitigates environmental pollution by solidifying harmful substances like heavy metals within the residual materials.

Pyrolysis raw materials oil yield

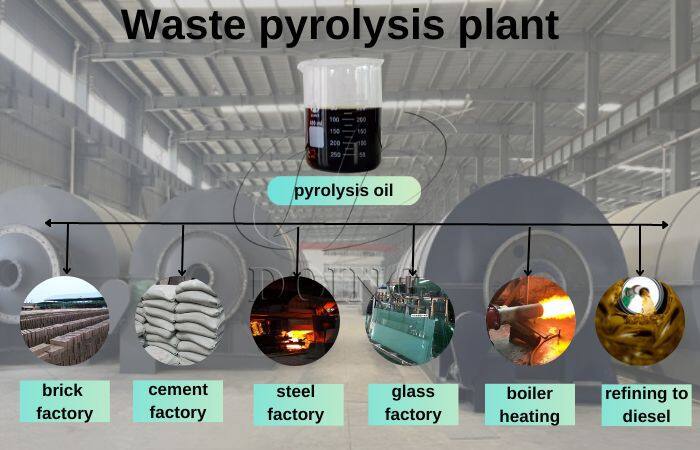

Applications and Advantages of Pyrolysis Oil

Pyrolysis oil offers multiple advantages across various sectors:

Energy Production: Pyrolysis oil can fuel boilers and furnaces, providing a cleaner energy alternative.

Biofuel Production: Serves as feedstock for manufacturing renewable, eco-friendly biofuels.

Industrial Applications: Functions as a binder in bio-coke production within the metallurgical industry.

Environmental Benefits: Reduces landfill waste and greenhouse gas emissions by converting waste into usable energy.

Applications of Pyrolysis Oil

DOING's Commitment to Innovation

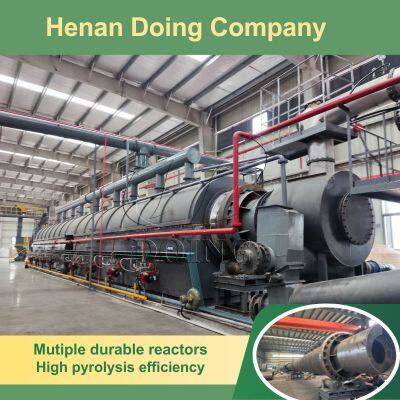

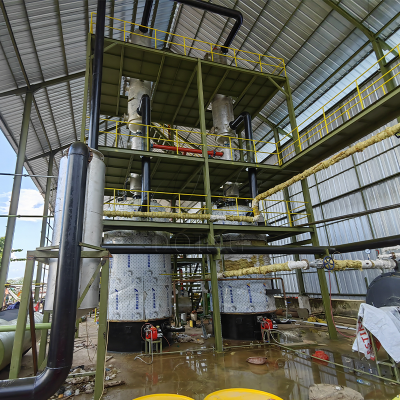

At DOING, we are continuously dedicated to advancing pyrolysis technology to maximize both the yield and quality of oil products. Our advanced pyrolysis units are engineered for efficient processing of diverse feedstocks, ensuring superior equipment performance with minimal environmental impact.

DOING pyrolysis unit manufacturer

In summary, pyrolysis is a versatile and sustainable method for producing valuable oil products from waste materials. Whether applied to plastics, tires, or oil sludge, the resulting oils play a crucial role in meeting the growing demand for clean, renewable energy solutions.

Recently Posted

-

Why is Oxygen Not Needed in Pyrolysis?

February 24, 2026Pyrolysis involves thermal breakdown of substances in an environment lacking oxygen or other reactive gases. The key factor for av Read More

Read More -

Key Considerations in Pyrolysis Machine Costs and Purchase Decisions

February 5, 2026The cost of pyrolysis machines is influenced by a range of factors, including machine type, processing capacity, material qua Read More

Read More -

The Superior Advantages of Plastic Thermal Cracking Compared to Conventional Recycling Methods

January 30, 2026Plastic pollution represents one of today’s most urgent environmental issues. Although conventional plastic recycling plays a role Read More

Read More -

Is Pyrolysis Oil Usable as Fuel for Cars or Vehicles?

January 21, 2026Pyrolysis oil, produced through thermal decomposition of waste materials like tires and plastics, isn’t suitable for direct use in Read More

Read More