The Profitability of Plastic Recycling Utilizing Pyrolysis Technology

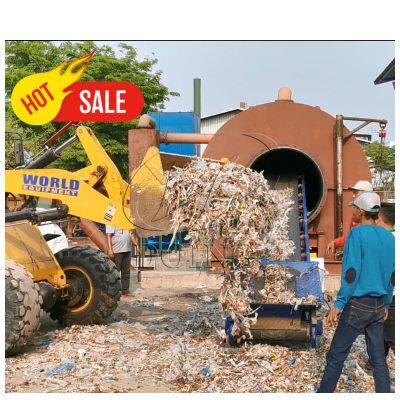

In today's environmentally conscious world, plastic recycling through pyrolysis technology presents a lucrative business opportunity while addressing the critical issue of plastic pollution. The financial success of such ventures hinges on multiple variables that must be carefully managed to maximize returns.

Critical Elements Influencing Financial Success

Plastic Feedstock Expenses

Procurement Channels: The expense associated with obtaining plastic waste fluctuates considerably based on sourcing strategies. Establishing partnerships with local waste management authorities or industrial complexes can significantly decrease acquisition costs. In certain scenarios, waste plastic may even be acquired at no cost, dramatically enhancing the venture's profit margin.

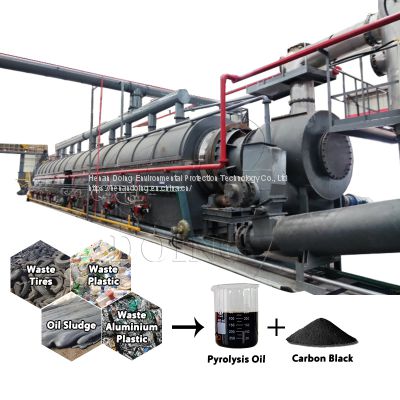

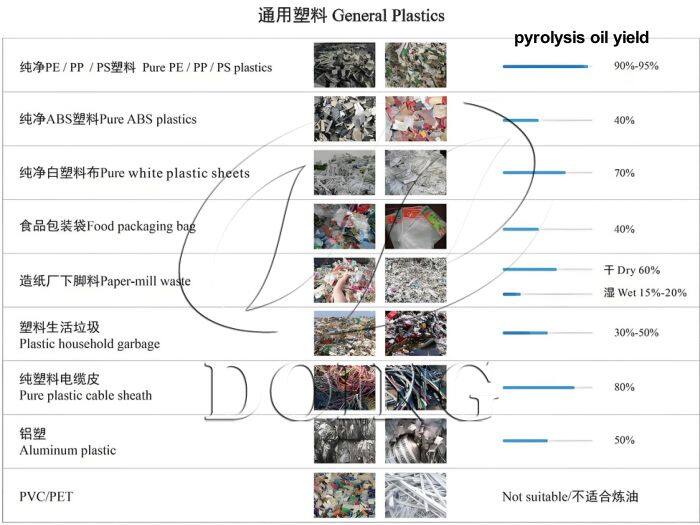

Plastic Type Suitability: Not all plastic varieties are equally effective for pyrolysis. Polyethylene (PE), polypropylene (PP), and polystyrene (PS) are optimal choices due to their superior oil conversion rates. Conversely, polyvinyl chloride (PVC) and polyethylene terephthalate (PET) are less desirable owing to their inferior yield performance and ecological concerns.

General plastic pyrolysis oil yield

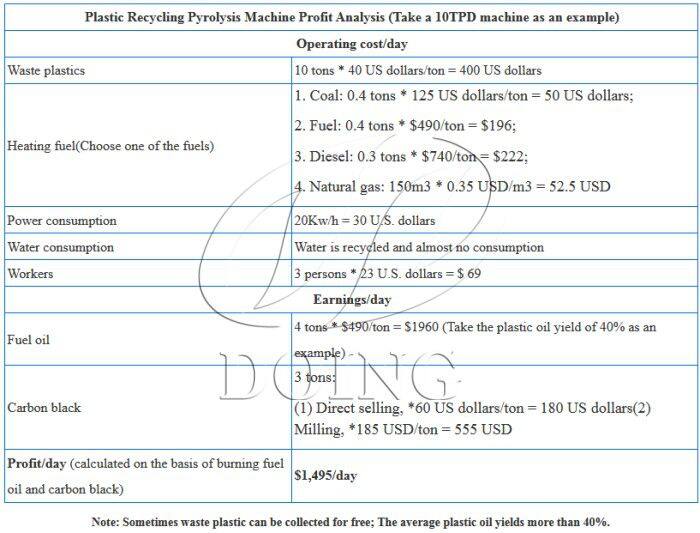

Operational Expenditures

Energy Requirements: Pyrolysis systems necessitate energy for their operation, making utility costs a substantial component of overall expenses. Implementing energy-efficient machine designs and operational protocols can substantially reduce these costs. Additionally, the synthesis gas (syngas) produced during the pyrolysis process can be repurposed to heat the reactor, thereby minimizing operational investments.

Equipment Upkeep: Consistent maintenance and periodic repairs are vital for sustaining machine efficiency. Investing in high-quality equipment and implementing a robust maintenance program helps reduce downtime and repair expenses.

Workforce Requirements: The number of personnel needed to operate and manage the pyrolysis process directly impacts overall costs. Implementing automation technologies and providing comprehensive staff training can enhance operational efficiency and profitability.

Plastic recycling pyrolysis machine profit analysis

Income from Derived Products

Liquid Fuels (Pyrolysis Oil): As the principal output of the pyrolysis process, this product can be marketed to various sectors such as transportation and manufacturing. The demand for pyrolysis oil is on the rise, fueled by the growing preference for sustainable energy solutions.

Carbon Black: This valuable byproduct finds applications in tire manufacturing, rubber goods, and ink production, providing an additional revenue stream. High-purity carbon black can fetch premium prices in the marketplace.

Usages of plastic recycling machine outputs

Market Dynamics

Domestic and Global Demand: A comprehensive understanding of the market requirements for pyrolysis-derived products, both locally and internationally, is essential. Regions with stringent environmental regulations often demonstrate greater support for plastic recycling initiatives and the utilization of recycled plastic products.

Competitive Landscape: The presence of competing plastic recycling facilities in the area can influence pricing structures and market share. Businesses can gain a competitive advantage by focusing on superior product quality or operational cost efficiency.

Plastic recycling operations employing pyrolysis technology hold significant profit potential when critical factors such as feedstock costs, operational efficiency, market demand, and regulatory compliance are effectively managed. By concentrating on the production of high-quality outputs like liquid fuels and carbon black, and by maintaining a keen awareness of market trends, companies can optimize their profitability in the plastic recycling sector.

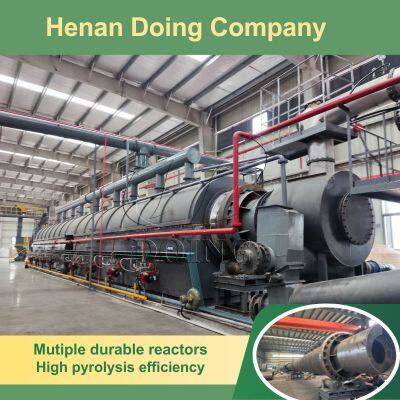

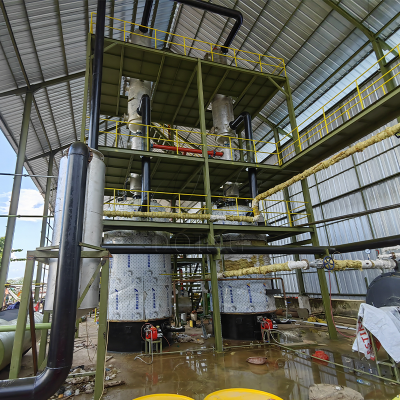

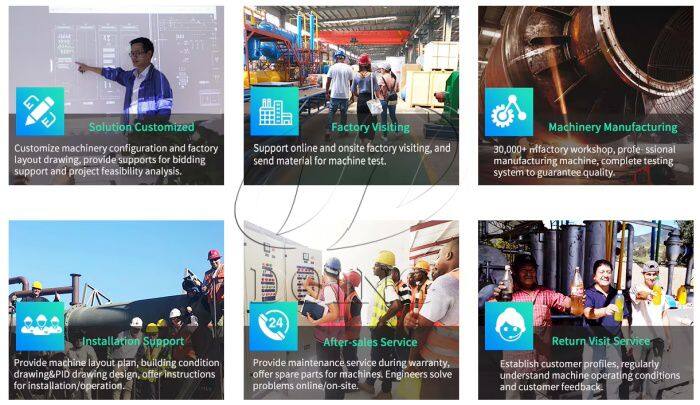

DOING waste plastic recycling pyrolysis machine manufacturer services

At Henan DOING, we are a seasoned manufacturer and supplier of pyrolysis equipment. Our dedicated business and engineering teams collaborate to devise customized solutions for each client, having successfully assisted numerous customers in establishing thriving plastic recycling pyrolysis businesses. If you are contemplating initiating a plastic recycling project, we invite you to contact us for professional guidance and support.

Recently Posted

-

Key Considerations in Pyrolysis Machine Costs and Purchase Decisions

February 5, 2026The cost of pyrolysis machines is influenced by a range of factors, including machine type, processing capacity, material qua Read More

Read More -

The Superior Advantages of Plastic Thermal Cracking Compared to Conventional Recycling Methods

January 30, 2026Plastic pollution represents one of today’s most urgent environmental issues. Although conventional plastic recycling plays a role Read More

Read More -

Is Pyrolysis Oil Usable as Fuel for Cars or Vehicles?

January 21, 2026Pyrolysis oil, produced through thermal decomposition of waste materials like tires and plastics, isn’t suitable for direct use in Read More

Read More -

How Does a Waste Oil Refining equipment Operate and What Are Its Benefits?

January 14, 2026Waste oil refining equipments are pivotal in recycling and refining waste oil. They can convert waste oil, crude oil, and eve Read More

Read More